|

| ...by F1 cars. |

I took a spontaneous trip to the F1 Canada Grand Prix, the only F1 race held in North America. It turned out to be a very rainy weekend, but even so the F1 cars were impressively fast and loud:

It's literally not possible to capture the sound of an F1 car passing 15 feet in front of you with my camera. The microphone just saturates and it just sounds like an explosion. Then again, that's sort-of what it sounds like in real life too, when your eardrum saturates. Combine the sound with the ominous sprays of water shooting 20 feet above the treeline on the far side of the track and it's like something out of a monster movie: You know it's coming for you next. Max has a more thorough summary of the experience, plus some better video.

But since we ran into car trouble (lol) on the way back from Montreal, I've had to spend a few days catching up with work. I made a bit of progress on some projects before and after the weekend, but not enough to justify an entire post for any individual one. So, I will do the thing I hate doing and make a Pan-Project Update tomake excuses for highlight the lack of progress on each.

First and easiest,

But since we ran into car trouble (lol) on the way back from Montreal, I've had to spend a few days catching up with work. I made a bit of progress on some projects before and after the weekend, but not enough to justify an entire post for any individual one. So, I will do the thing I hate doing and make a Pan-Project Update to

First and easiest,

Sensorless Field-Oriented Control

I've made no progress on this. I have a decent idea of how to start, and I maintain my opinion that you can do pretty much anything in software if you spend enough time messing with it. Some day soon I will do it, and nobody will care because it's software and has no tangible meaning, but then I'll just laugh at everyone.

Moving on then,

Flinch

I got the M3 screws I needed to finish mounting Flinch's four gearmotors, so I did that:

Flinch is a straightforward 4WD robot layout, so there were no surprises here. It's essentially the same size and shape as mini4WDbot:

In fact, as a starting point I just transfered mini4WDbot's entire electrical system over to Flinch. That includes four repurposed VS-11 servo drivers, an Arduino Nano Carrier, and a 7.4V LiPo. I wanted to test the open-loop performance of the FingerTech mini-Mecanum wheels before investing significant effort into the inertial sensors for high-speed Mecanum-ing.

Unfortunately the low-speed tests didn't work out so well. I've worked with larger Mecanum wheels before and even those are very sensitive to weight distribution, driving surface, and the condition of the rollers. The rollers on these wheels are rubber with brass axles riding in plastic wheel hubs. Off the ground, they roll just fine. But under axial loading, the steel washer spacing the rubber roller out from the wheel does not make a very good thrust bearing. Maybe with a lot of tweaking they might do something Mecanum-like, but I don't have the patience for that.

Plan B involves putting real rolling-contact bearings on each roller axle. FingerTech sells these (an implicit admission that the regular axles leave something to be desired?), but they're needle bearings, which won't help much with friction between axial-contact surfaces. So I instead opted for SR144ZZ tiny ball bearings. At least with these I can use tiny shaft spacers to keep the washer from making contact with the side of the wheel. Of course, this means carefully drilling out each roller axle and pressing/gluing in a tiny bearing. After that, another open-loop test to evaluate the new level of Mecanumosity.

Next,

Next,

DirectDrive

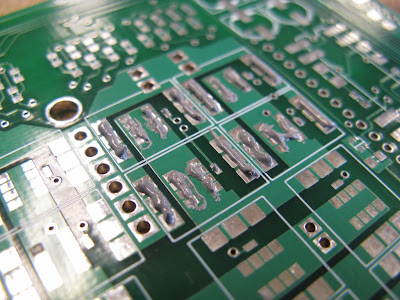

I'm starting work on my larger motor controller, called DirectDrive because it uses a crapload of DirectFETs. I ordered a single board for testing, since usually my v1.0 motor controllers wind up failing spectacularly in some way anyway. But I can still be hopeful, right? Plus, I get to play with a new toy:

Add it to the list of things that are absurdly cheap if you buy them from China, a bagel toaster programmable reflow oven. DirectFETs cannot be soldered with an iron, since the gate and source pads are under the device. I was planning to use a hot air station, but this is way faster and I've never done it before so it was an opportunity to learn. It's pretty simple:

|

| Step 1: Apply paste haphazardly without a stencil. |

|

| Step 2: Place MOSFETs in the correct orientation. |

|

| Step 3: Toast for 7 minutes or until lightly browned. |

Actually there are a few little DirectFET-specific tricks I learned along the way that I would definitely use in the future:

- DirectFETs are ever so slightly magnetic. This is great because you can pick them up with a small neodymium magnet (instead of tweezers) and carefully lower them onto the paste. Once they touch the paste, surface adhesion is enough to pull them off the magnet.

- You can look at the board edge-on to verify that there is still a gap between the gate and the nearest row of source pads. If not, you probably want to clean off that one and try placing it again. After reflow, this gap is usually still visible. I did see a few after reflow where the gap was no longer visible. But upon measurement, they did not appear to be shorted.

- The drain tabs and source pads need a lot of paste. Screw stencils.You can lay down a thick line. It's got to conduct a lot of current anyway, and much of the volume of the paste is flux, so it gets thinner as it evaporates. It's not like a BGA IC where you have to worry about shorting adjacent balls. There is only one critical point (between the gate and source) and by preferentially steering the line of solder paste toward the far side of the source pads, you can avoid bridging that.

- You can and should test the MOSFETs after they have been reflowed. I test to make sure there are no shorts from gate to drain or gate to source. (If you shorted drain to source, you did something terribly wrong.) I also check the capacitance from gate to source, which should be near the datasheet spec and consistent across all FETs. And finally I check the on-state resistance.

As far as alignment goes, some of the FETs are visibly rotated by a few degrees. However, they are very flat, something I was concerned about for heat sinking. I'm happy with the procedure and will be even more confident in recommending it after I load test this board.

One minor problem was that the ACNW-3190 gate drivers that I was so excited about last post turned out to be 400mil DIP packages instead of 300mil. I should have RTFDS more carefully. Anyway, that means I will have to go back to the 2.5A HCPL-3120 drivers. Though maybe I can, you know, stack them on top of each other or something.

And finally,

???

The mysterious four-wheeled Edgerton Center Summer Engineering Workshop 2011 project. It's not quite ready for a reveal yet, but here's a teaser:

And finally,

???

The mysterious four-wheeled Edgerton Center Summer Engineering Workshop 2011 project. It's not quite ready for a reveal yet, but here's a teaser:

bye the way, I live 10 min away from the Grand Prix. I am in Longueuil for my summer intern!

ReplyDeleteSo you have 8 mosfet per motor phase. 2 groups of 4 mosfet.

Did you take the worst case of 26A x 4 = 104A then you have two set working so 208A total?

right?

(26A is Surface mounted on 1 in. square Cu board, steady state.) And on page diagram 3 they write "still air" That is having the heatsink made of cooper. You are going to have a big heat sink, so that will be 113A at 100C or 160A at 25C. So that is (113A*4)*2 = 904A? or 1280A...

Wow! I should have come visit. I bet you can hear the cars (at least the F1 cars) from there.

ReplyDeleteI wish 904A. The problem is all FETs share one heat sink, so if the heat sink only has some certain area and heat dissipation ability, it will be less than the sum of all the FET individual ratings.

Also the ratings don't account for switching losses, which are pretty high because of the large gate capacitance of four FETs in parallel. Then also noise spikes get worse as current goes up, even if the FETs would otherwise be fine. I think 200A is a reasonable goal, and will be happy if I get more.