I acquired lots of wheels this week.

The motivation: With

so many scooters being built around here these days, I felt left out. Not that I don't have an electric scooter already; amazingly

BWD still works just fine. Or rather, the only problems with it are more fundamental ones that can't really be fixed. For one, the frame, especially the folding joint and its mount to the deck, lacks complete rigidity. But most noticeably, the wheels are flat, 1.5"-wide slabs of 1/4"-thick, 80A-hardness polyurethane. That's not much shock absorption, and makes for a particularly unenjoyable ride on anything but smooth asphalt. Not to mention the impending fatigue death of the motors, frame, and electronics.

I don't think this is a problem with BWD's design, specifically. Kick scooter wheels in general are not designed with ride comfort in mind. I don't plan on doing any offroading, but I really would like a kick scooter-sized stealth EV that can operate equally well on asphalt, bad asphalt, and sidewalk. It would make commuting around Cambridge much more feasible. So I started investigating alternative wheel options in the 6" range, to allow for BWD's motor size plus some additional compliant material of some type.

Wheel Option #1: The Reach

The McMaster Tweel

This was the most risky and ambitious option. (Since I'm already talking about it in past-tense, you know there's a catch.) It's a

tweel, which is a special type of compliant solid wheel. This particular one is a 6"x2" model from

McMaster-Carr (#5002T63). It was a $100 gamble, since I had only the crappy McMaster sketch to go on. And, well, I lost. It's actually really hard. Even with the tweel ribs, the 95A urethane would not yield any smoother a ride than BWD's wheels. I guess I should have inferred that from the load rating of 1,000lbs. The profile is also flat, which makes turning more awkward. Oh well. It makes a really cool desk ornament, and might some day be useful for something, so I'm not returning it.

Verdict: Useless for scooters, but good for impressing office visitors.

Wheel Option #2: McMonster Truck

This is also in the 6"x2" category. It's actually part of a McMaster-Carr caster (#22925T18). It's a rather wide aspect ratio for a kick scooter wheel. (Razor scooter wheels are more like 4"x1" or 5"x1".) It's not as absurd as BWD's 5"x2", but it's still not as sleek as I would like. It is pneumatic, though, which offers far superior shock absorption than solid urethane tires. Other things it has going for it are a durable low-profile tire and an easy-to-work-with rim with a flat reference surface for attaching a custom hub.

Verdict: Durable and easy to work with, but not aesthetically appealing.

Wait. Wasn't there a good reason why it's difficult to add hub motors to small pneumatic wheels?

Oh, right. That.

Yeah, a pneumatic mini-wheel-motor-thing would have to contend with the valve stem of the inner tube, which invariably protrudes into the space that would normally be occupied by the motor. On bikes, this is no problem, since the hub motor is much smaller in diameter than the wheel. But on a scooter, you need as much motor volume as possible to get power out of such a small device. The torque is limited by size and the speed is limited by lack of any gearing, so having a large air gap to outer diameter ratio is important. (If you want to learn more about how to design a miniature in-wheel motor, you should read this Instructable.)

I seriously debated just putting a belt and pulley on the thing and calling it a day. But the direct drive solution is just so much more appealing now that I've seen it work a few times. So, a compromise: a direct drive motor coupled to the non-valve-stem side of the wheel. It should occupy not much more volume than a timing belt pulley, but will run

silently for ultra stealthiness. Whether you want to think of it as a motor attached to a wheel or a wheel attached to a motor is up to you. I would still call it a hub motor, since it is an outrunner directly coupled to the rim. Since the motor will occupy some extra axial length, a wheel thinner than 2" would be preferable. Which brings me to...

Wheel Option #3: Not to be used above 3MPH.

This is a light-duty pneumatic caster from aptly-named

Caster City. What I really like about it is that, from far away anyway, it looks like a kick scooter wheel. But, it's really a 6"x1.25" pneumatic tire. Here's a profile comparison of Wheel Options #2 and #3:

The smaller wheel is also significantly lighter due to the plastic hub. My first impression was that it would be virtually impossible to adapt this hub to a custom hub motor, since it has no flat surfaces to work with and the crappy bearings looked integral to the hub. Turns out the bearings were so crappy that they popped right out with little effort...

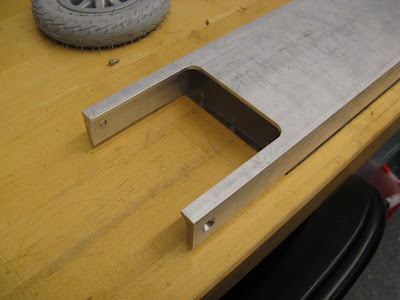

...leaving an actual flat and cylindrical reference surface! Somewhere to start, at least. But wait, there's more. That pocket is actually exactly the same size as the bearing pocket in BWD, so it could potentially accept the same 1/2" ID bearing. I was not planning on using the wheel rim as part of the motor structure (in fact, I was actively avoiding this), but in this case it's just so tempting. What would be required, then, is a way to attach rotor plates to the wheel itself without putting too much load on the thin-ish plastic rim. MITERS whiteboard free body diagram:

Definitely not to scale. The motor should be thinner than the wheel.

First of all, I know there are three bearings on that shaft. Let me finish, Kanye. Force from the ground goes through the tire and rim, then into the two wheel bearings and the shaft, where it is carried out to the mounting forks. (Remember, in this design the shaft is stationary.) The motor itself is merely hanging off the wheel, screwed into the rim through an adapting plate. The third bearing helps align and support the motor, but ideally should not be carrying much of the ground reaction force. I know that if the entire thing is modeled as a rigid body, this doesn't work. But in real life, accounting for rim compliance, I think this makes the most sense. (There is an analogy to power/signal ground loops in here somewhere...)

So, it's a risky mounting solution, but it would be very compact. The windings would actually stick a bit into the volume of the wheel, so it is more like an in-wheel motor than the rest so far. I would worry about using the plastic rim as an important structural component of the motor, though. And the there's also this:

...I will blatantly violate this warning (at my own risk).

Verdict: Lightweight and stealthy, but of questionable structural integrity.

Wheel Option #4: What is it?

This

Edmond Wheelchair caster caught my eye, and not just because it's red. It's a latecomer to my wheel party, so I don't have a physical one to play with yet, but the Shox tire is interesting. It's a flat-free pneumatic alternative that may offer similar shock absorption, according to the website. I won't know for sure until I get it. In any case, the hub looks very similar to Option #3, so motor mounting provisions should be the same. This one doesn't have a valve stem, though, so everything is still on the table, including a completely in-wheel motor.

Verdict: Jury still out until I see it up close.

That's it for the wheel report. Next post should be the decision. I will also detail the motor plans a bit more, but it will essentially be BWD leftover hardware: