"Hey Shane, why don't you build a larger controller that does more current?"

-Everyone.

Because...I...don't.....ok, whatever.

Rather than mess around with a new

3ph revision, I'm just going to start a brand new controller series, to try out some of the crazy stuff I've been wanting to try that's too risky to test on controllers I actually need. 3ph v3.1 works nicely at 40V and 40A. It's finally free of noise issues and has been running on

Pneu Scooter for almost half a year now. But in the interest of satisfying some more demanding brushless motor applications, I'm shooting for 50V (DC) and 200A (peak phase current). So I'm going back to v1.0 and I will call this series DirectDrive...

...because it uses a crapload of DirectFETs. DirectFETs are one of the big things I've been meaning to try out on a motor controller. They're an

International Rectifier proprietary package that eliminates plastic and bond wires in favor of...just...metal. It's about as minimalist a package for a

power MOSFET as you can imagine, and in addition to low resistance due to increased die area, they can also get rid of heat more easily thanks to exposed metal cans that can be directly attached to a heat sink.

|

| They're also less than 0.7mm tall. |

The particular part being used on this controller is the

IRF7759L2TRPbF, a 75V FET with a typical on-resistance of 1.8mΩ. There are four in parallel for each leg of the three-phase bridge. The layout is one I've been thinking about for a long time that uses the DirectFET package (can) as a sort-of bus bar to augment the current-carrying capability of the traces and to jump the three phase outputs across the negative bus to the outer edge of the board:

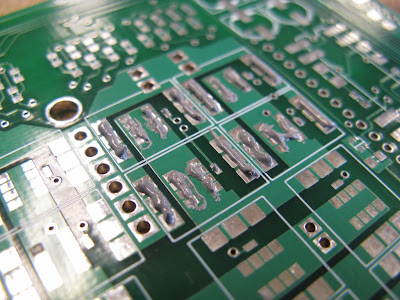

It even looks like a three-phase bridge. The phases are arranged in three columns and the phase output is the giant strip of through-hole pads at the bottom edge of the board. All the high side FETs are connected together at the can (drain). There are traces that link them and the bus capacitors on the top of the board, but for the most part current will go straight through the cans themselves. Likewise, the phase outputs jump over the negative DC rail by way of the low-side FET cans. Conductive FET packages are like having an extra PCB layer to play with. Of course, the can resistance (measured to be about 0.15mΩ) will add to the total heat dissipation.

|

| Here's what it looks like on the bottom. |

One of the risks of using the DirectFETs that's prevented me including them on a controller so far is the fact that they are impossible to solder with an iron. The gate and source terminals are on the underside of the FET. IR has a

33-page app note entirely about how to reflow the DirectFET packages. I don't have regular access to a reflow oven, but

this video convinced me that it would be possible to do with just a hot air station. I tried it out on one of

Matthew's test boards, without the stencil, and it seemed to work okay. The measured resistance after soldering was about 2mΩ. How the array of 24 will behave, especially in terms of overall straightness and flatness post-soldering, will be an interesting experiment.

The reason flatness came to mind as a potential problem is because of the massive heat sinking requirement of this board. Even if it were 99% efficient, a 50V/200A controller would have to shed 100W somehow. The DirectFETs provide plenty of area for extracting heat, but we're still talking about the sort of cooling requirements you'd have in a beastly processor. So, what isn't pictured above is the sizable heat sink and fan that will be required to actually run at 200A for any extended period of time. For a quick burst, though, the 1/4" slab of aluminum will provide some thermal mass buffering. Between the sink and the FETs will be a 0.5mm silicone thermal interface material, to fill the gaps and isolate the sink from the electrically conductive cans.

This will also be, oddly enough, the first controller I've ever designed with on-board temperature measurement. I wanted to use a linear temperature sensing IC instead of having to calibrate thermistor curves, but they don't make one that would fit in the gap between the board and the heat sink...

...

oh wait yes they do. The TMP20 sensor from Texas Instruments is a mere 0.5mm tall, making it actually

shorter than the DirectFETs. On the board, it takes up less than 2mm x 2mm, which means it's basically invisible and probably very difficult to solder.

|

| The thing next to it is a 0603 thermistor... |

Because it basically doesn't even exist, I could put it in a tiny gap at the intersection of the high side and low side FETs on one of the phases. It will be in contact with the heat sink, and has a local ground plane to conduct heat into it. But it's so small that it probably instantly assumes the temperature of whatever it's touching anyway. It's also right next to the logic side of the board, allowing easy access for 3.3V, signal ground, and the analog output. Just in case it folds itself up into nothingness or explodes due to dV/dt induced nastiness, I put a 0603 thermistor footprint right next to it.

The power layout of this board was probably one of the most fun layouts I've done, ever. I had it basically finished a few weeks ago, after I converged on a very nice interleaved bus capacitor arrangement:

You might have to use your 3D imagination skills a little here. It jumps between layers a lot. The vias will need to be filled with solder to carry the full current, but I think that's standard practice for high power-density controllers. There are five 18mm surface-mount electrolytic capacitors on board for a total of 3300μF at 63V. The capacitance is high enough, but the ESR may cause problems running at 200A. External capacitance is not out of the question. Additionally, there are software games you can play to minimize the ripple on the bus capacitors in a three-phase inverter.

I have no idea how it will perform, but I also really like the way the gate drive escapes from the power section up to the top of the board. Crossing over traces under the capacitors frightens me a little bit, but it cleans the layout up nicely and I think gate signals are low-enough impedance to blast through any EMI issues. I think...

Speaking of EMI, although the 3ph controllers since v3.0 have made good use of the

IRS21844 half-bridge integrated gate drivers, I've decided to retreat to the comfort and safety of the optocoupled gate drive that I used in

3ph 2.1 and, the ultimate FET killer,

Cap Kart. The idea is fairly straightforward:

Each MOSFET is driven by a gate drive optocoupler, formerly the

HCPL-3120. The output of the gate driver is a push-pull driver that runs on 15V, either directly from a 15V supply (low side) or a bootstrap capacitor (high side). The input is just an LED. If the LED is on, output is driven high, if off, the output is driven low. The LEDs are connected in anti-parallel. A simple inverter and low-pass filter circuit ensures that a) both LEDs can't be on at the same time and b) there is a suitable delay between turn-off of one LED and turn-on of the other. This is passive shoot-through protection. Importantly, the logic side is entirely isolated from the noisy power side by virtue of the optical interface.

Switching four parallel IRF7759L2TRPbF FETs is a tall order for the 2.5A HCPL-3120, though. The total gate charge per FET is 200nC and the "switch charge" is 73nC. Even if the gate driver were operating at 2.0A for the entire switching period, it would take 4*200nC/2A=400ns to fully turn on or off the FETs. It's similar in switching effort to Cap Kart's half-bridge, but unlike Cap Kart it's being designed to run at 15.6kHz and has three phases.

|

| This is not a happy gate drive. |

Avago Technologies to the rescue. It's been a couple years since I browsed the gate drive optocoupler selection, and in that time a new, 5A version has come out. The

ACNW3190 is more-or-less pin compatible with the HCPL-3120, and should be able to switch the four parallel FETs in a more reasonable amount of time. This will be the first time I'm trying them out, though.

There's one more "new" trick I am trying out, probably the most risky one of all. You may have noticed the odd, broken traces on the A and C phase:

And the islanded SOIC8 chip on the top layer. This is, in fact, an attempt at through-the-board Hall effect current sensing. The chip is a

LEM FHS 40-P current sensor. Actually, it's more like a magnetometer, measuring field strength to the right, looking down on the chip. The traces passing under the chip produce a magnetic field according to the right-hand rule.

I've use Hall effect current sensors before, but never a remote-sensing one like this. It is a little worrying because they can easily pick up stray magnetic fields. I've taken a few steps to minimize this: I used the A and C phases to keep them as far away from each other as possible. Also, all the power wires leave the board perpendicular to the current-carrying traces designed to be sensed. This way, they do not contribute to the measured field. Presumably, any static errors can be calibrated out, but there's also the potential for external fields from things with magnets in them, like perhaps motors. Of course, this would be a problem with regular Hall effect current sensors as well. Only one way to find out how they perform.

Oh yeah, I forgot to mention the purpose of the broken traces. The FHS 40-P is designed for, at most, 100A sense current through the board, with a single large trace running directly under the center of the chip. At the definite expense of resolution and the possible risk of lower noise immunity, I'm trying to sense an even larger current by moving the current-carrying wires farther away from the center of the chip. The broken traces can be selectively jumpered to "program" the gain of the current sensor to my liking.

To improve the noise immunity of the current sensor signal Because I am too lazy to route the traces, the current sensors are actually connected to the logic side of the board via external three-wire cables, almost as if they were separate modules altogether. As an added bonus, if they don't work out, I could possibly use external current sensors anyway. Though in reality I would probably consider that a big enough failure to merit a v2.0 design revision. The two phase currents, as well as the Hall effect encoder and throttle signals, come in to the logic board via two rows of headers:

There's also an auxiliary current sense input which could be used for sensing DC current, as well as a spare analog channel. Differential voltage sensing is also available, though it comes in through a separate input near the bottom of the logic section. The logic board and power supply are the same as on 3ph 3.1, including the

DCR021205 isolated regulator that saved the day last time. It will run my field-oriented control code for the STM32F103, so there shouldn't be any software surprises.

The entire controller is just about 4"x3"x1", or one standard EAGLE brick. (3ph 3.1 is an EAGLE half-brick.) The power to area ratio is quite high, which means that cooling will be a big challenge if it is to actually run at 200A. But even having a nice 100A continuous controller around will be handy, I think.

Board have been ordered. Actually, since it's v1.0, I only ordered one board. For some reason, my v1.0 motor controllers never seem to work. (And I know v1.0 of everything is usually not a complete success, but I'm talking about spectacular failures here.) So I'm not going to get my hopes up right away. But it's nice to finally be working on motor controllers again.