in New York, along with some of the other builder-types from MIT and the Summer Engineering Workshop crew. Needless to say, we were responsible for most of the rideable objects on our side of the Faire:

I've been to the

Cambridge Mini Maker Faire twice, but this was my first experience with one of the three World Maker Faire events. While the Mini Maker Faire probably attracts a crowd of a few thousand, the World Maker Faire numbers must be in the several tens of thousands. First off, I was amazed that a handful of people actually knew me from my blog, so here's a shout-out to the people who came by my table to say hi. I'm not as famous as

certain people, but it's cool to meet my blog readers in person.

Also present was

Max H., who brought

TOBL to show off, and most of the

tinyKart crew. A large sampling of the

MITERS builders came down from Cambridge as well to show off a

pair of sound-reactive EL shutter shades,

giant Tesla coil driver,

3D printer,

battlebot,

tankboard,

hub motor kick scooter, eddy current clock, and

rideable freakin' hexapod.

For my part, I decided that I would attempt to bring

five projects. First, my three Maker Faire veterans,

Pneu Scooter,

Twitch, and

SegStick. Additionally, I brought

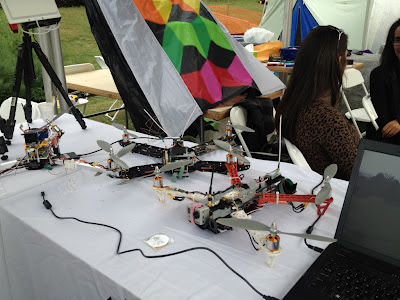

4pcb, which turned out to be an attention-getter even though I did not even attempt to fly it. I would say that quadrotors are the new Segways - the current obsession of every random tech-savvy person. But in fact, Segways are still the new Segways. For some reason, no matter what else I bring, I can't escape the Segway people. Then again, I've said a few times that the quadrotor is just two Segways and a FIRST robot, so maybe it's all inherited from one parent class of silly self-stabilizing objects.

So before I get angry,

Yes, it does have an angular rate sensor, commonly known as a "gyro" for historical reasons. No, there is no mechanical flywheel keeping it balanced. No, it does not use a Kalman filter. And yes, it runs just fine on an Arduino, and it doesn't even use that much of its processing power because the code is very, very simple...much simpler than you want to think.

And that's all I want to say about quadrotors and self-balancing platforms. But here are the Maker Faire recaps for the more interesting projects:

tinyKart:

That's tinyKart in the trunk of a Ford Fusion. I loaded it into the trunk myself in about 10 minutes. It involved taking out 12 cap screws and sliding the two halves apart, then flipping the front half over so that the steering wheel rested in the seat. The back half weighs less than 40lbs and the front half weighs less than 20lbs. There was even enough extra room in the trunk for

Tyler's monster Tesla coil driver.

In terms of making an ultralight, ultra portable go-kart, I consider this trip a huge success. We like to make things that don't exist, and an ultralight electric go-kart is something new. There is the

Razor Ground Force, which is the same weight (55lbs) as tinyKart but there really is no comparison. Which brings me to my next point:

tinyKart is absolutely freaking awesome as a go-kart.

|

| Just look what reverse did to this dude's hair... |

We drove it all weekend and it is actually amazing to me that we built such a thing from scratch. It's a totally different experience from

Cap Kart and most other go-karts I've driven, and it's more fun than any of them. "Sprightly" might be a good word. I really don't know. It darts around in ways that defy its narrow tires and flex-y frame. The acceleration is good too, despite the lack of

more formidable brushless motors. The trigger throttle just makes it even more of a unique experience. And the brakes are so good that I worry about bending the steering wheel from the deceleration force. I really would not change a single thing about the mechanical design...it's pure win.

|

| "If it's going to break, it's going to break now." -Max |

It even does things it shouldn't, like off-roading. We took it on slippery grass and dirt, and it was even more fun than on asphalt. The flex-y frame doesn't mind at all and the 17mm aluminum wheel axles, which are probably the weakest link in the structural loop, survived both the shock load from bumps and side load from drifting.

Pretty much the only things that isn't 100% perfect are the controllers. Maybe I just have a high standard for motor control...well okay, I definitely do...but the Kelly controllers just aren't quite up to the task of driving full load into these motors. They cut out occasionally, leaving you with half power for a second or two. I'm learning the acceleration threshold that works, but the motors can handle more power so I feel the urge now to give tinyKart a set of controllers that can, too.

Pneu Scooter:

A few days before Maker Faire, Pneu Scooter got a flat rear tire. I knew it would happen eventually because the front tire got a flat about a month ago. Unfortunately, the 6" pneumatic casters are not conducive to easy tire/tube changes. I thought they would be, which was one of the motivators for using pneumatic tires in the first place, but as it turns out, barring special tooling, it's easier to change the entire wheel. So changing the rear wheel means taking apart the hub motor. But, really, Pneu Scooter has been ultra-reliable, so this is more like scheduled maintenance than a design flaw.

|

| Could use a cleaning while I'm at it... |

So I opened the motor for the first time since it was built. The process is pretty simple. The only tricky part is getting the three phase wires out, since they are soldered to connectors. To fit back through the bearing, they needed to be de-soldered and shoved back into the axle slot. Here are some pictures from the teardown, with everything dirty but intact:

|

| Windings. |

|

| Outer spacer. |

|

| Dirty rotor. |

|

| Awesome adapter ring. |

After taking off the adapter ring, I could get a good look at the rim and tire to see where the damage occurred. I suspected that the tire and tube had been punctured by screws that hold the ring onto the plastic rim. (The front tire suffered a similar failure.) Sure enough, I found a bunch of slashes like this:

I guess the screws were wearing through the tire and eventually the tube over time. The solution is so simple that I have no idea why I didn't do it in the first place.

|

| Duhhhh... |

So I put the motor back together with the shorter screws and Pneu Scooter was back up an running in less than three hours...

...which is great, because it actually came in really handy during Maker Faire. Not only was it the only one of my vehicles that I actually felt reasonably safe letting the annoying little kids ride, but it turned out to be the best way to get from the Citi Field parking lot to the Maker Faire itself. There were shuttle buses, but they were crowded and only took you about 60% of the distance anyway. So, I just took the scooter instead.

Twitch

Twitch also had some lingering wheel problems before Maker Faire. Specifically, the press fit holding the custom aluminum hubs to the plastic

Vex omniwheels had failed on one wheel, making it hard to drive. It's happened before and I've resorted to epoxy for a quick fix, but I wanted to make a more permanent solution before the Faire. So, I manned up and got on the lathe...

...and then the mill...

... to turn out some new hubs that will actually bolt onto the wheel instead of relying on a press fit into flimsy plastic. The six-bolt pattern lines up with the spokes such that 1/4-20 screws rest against the inside surfaces to positively transmit torque to the wheel. I only put on one new hub for now, but I have the full set for when the remaining press fits fail.

As I was doing this, though, some other problems revealed themselves. One of the linkages had a stripped-out hole, and one of the servos that drive the linkages was also damaged. I suspect both were symptoms of the wheels running into hard stops while the servo continues to drive the linkage. So far, I've only been calibrating the servos by hard-coding in soft-stop values, but they change every time I take the robot apart and put it back together.

|

| Twitchguts, if you don't remember. |

I decided that after replacing the servo and fixing the linkage, the best way to prevent this problem from happening again would be to just write the damn trim software the way it should be written.

Now the servos each have a software-settable minimum and maximum value. Through some coding trickery I was able to "or" the calibrate state with the normal drive states (forward, sideways, omnidirectional) so that you can trim the servo end positions while in any one of the states. This is useful since the servo maxima occur in the forward state and the minima occur in the sideways state. And just for extra software hacker cred, I save all the trims to a text file that automatically loads when the program starts up.

Twitch was, as usual, a constant source of entertainment that filled in the gaps well while the vehicles were charging. Part of the fun of Twitch is that nobody (or very few people) have ever seen a robot move the way it does. I am finally able to drive it in the way that it deserves, making smooth state changes and combining rotation and translation in ways that just look cool. It took a lot of practice, but I feel like Twitch is finally living up to its potential. And on that note I'll just leave this here...